Download

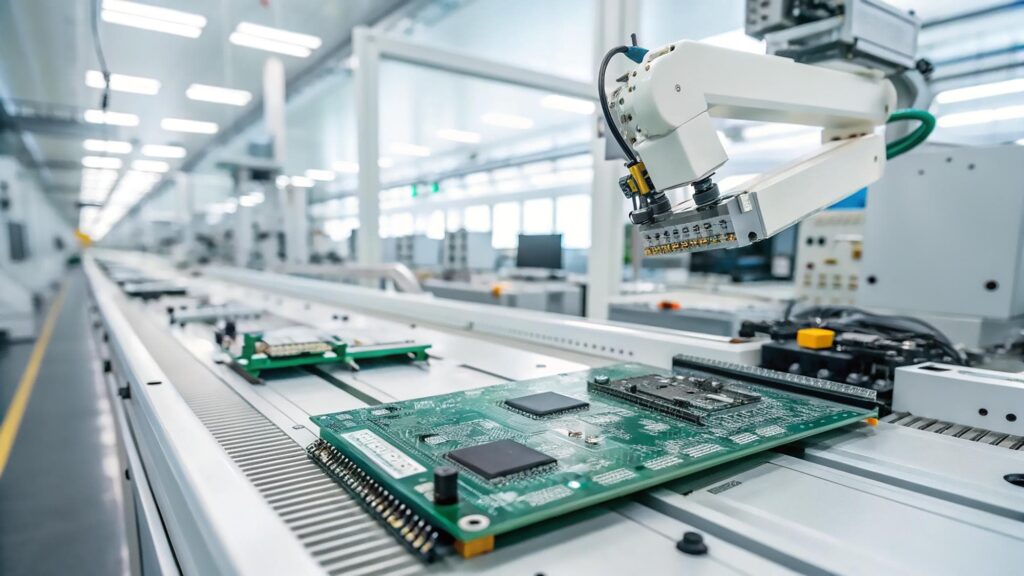

3. PCB Assembly & Build Capabilities

We offer full-spectrum PCB assembly services to support every stage of your product lifecycle—from rapid prototyping to mass production. Our capabilities ensure high precision, strict quality control, and industry certifications, making us a trusted partner across critical sectors such as medical, automotive, aerospace, and industrial electronics.

- Assembly Types

We provide a complete range of assembly solutions, including Surface Mount Technology (SMT), Through-Hole Technology (THT), and mixed technology (SMT + THT). Our SMT lines are equipped with high-speed pick-and-place machines capable of handling fine-pitch components, micro-BGAs, and 01005 package sizes. THT processes are ideal for power electronics and connectors requiring mechanical strength. We support single, double, and multi-layer PCB assemblies up to 24+ layers on a variety of board types including rigid, flex, rigid-flex, HDI, ceramic, and aluminium-backed metal-core PCBs.

- Component Handling

We are equipped to handle a wide range of components, including micro-sized 01005 and 0201 packages, fine-pitch ICs (down to 0.15 mm), BGAs, QFNs, CSPs, and other leadless components. Our facility supports the assembly of odd-shaped and custom components, ensuring flexibility for unique product designs. All component handling is done in ESD-safe environments with special provisions for moisture-sensitive devices (MSDs), including dry cabinets and humidity monitoring to maintain component integrity.

- Soldering Capabilities

Our advanced soldering systems are capable of both lead-free and leaded processes, depending on your product and regulatory requirements. We use precision reflow ovens with multi-zone thermal profiling for SMT soldering and wave/selective soldering for THT assemblies. Solder paste inspection (SPI) is integrated to ensure correct deposition, reducing defects early in the process. Our soldering practices strictly follow IPC standards, ensuring strong, reliable, and repeatable solder joints across all builds.

- Prototyping to Mass Production

Whether you're launching a new design or scaling up a proven product, we offer flexible production models to suit your needs. Our quick-turn prototyping services can deliver fully assembled PCBs in as little as 24 to 48 hours, helping you reduce time to market. We support low-volume, high-mix builds for startups and pilot projects, as well as high-volume production runs for commercial applications. Our New Product Introduction (NPI) process ensures a seamless transition from development to manufacturing with full traceability and support.

- Testing & Quality Control

We maintain strict quality assurance through a wide range of inspection and testing methods. Automated Optical Inspection (AOI) ensures accurate component placement and solder joint quality. X-Ray Inspection (AXI) is used for BGAs and hidden connections to detect voids and alignment issues. In-Circuit Testing (ICT) validates the integrity of electrical connections, while Functional Circuit Testing (FCT) checks device performance under real-world conditions. Additional testing includes First Article Inspection (FAI), burn-in, and environmental stress testing for long-term reliability.

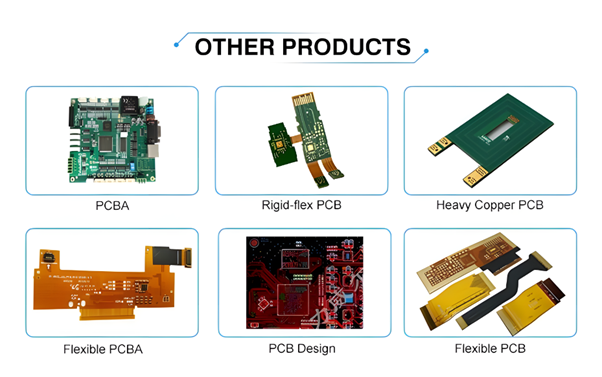

- Additional Capabilities

Beyond core assembly, we offer a range of value-added services to streamline your manufacturing process. These include conformal coating and potting for protection against moisture, dust, and chemicals, using silicone, epoxy, or acrylic materials. Our depaneling services include V-scoring, routing, and laser cutting. We also provide firmware flashing, device programming, and functional calibration. Whether you supply your own components or need full turnkey assembly, we offer both consignment and procurement-based models for maximum flexibility.

- Certifications & Standards

All our processes adhere to globally recognized certifications and standards. We are certified to ISO 9001 for quality management, ISO 13485 for medical devices, IATF 16949 for automotive manufacturing, and ISO 14001 for environmental management. Our RoHS and REACH compliant workflows ensure environmentally responsible practices. Where applicable, we also support UL-certified assemblies. All builds follow IPC-A-610 Class 2 or Class 3 workmanship standards, based on your application’s criticality.